Machinist

This is a {Advertised Permanent / Temporary}, {Advertised Full Time / Part Time} vacancy that will close in {x} days at {xx:xx} BST.

The Vacancy

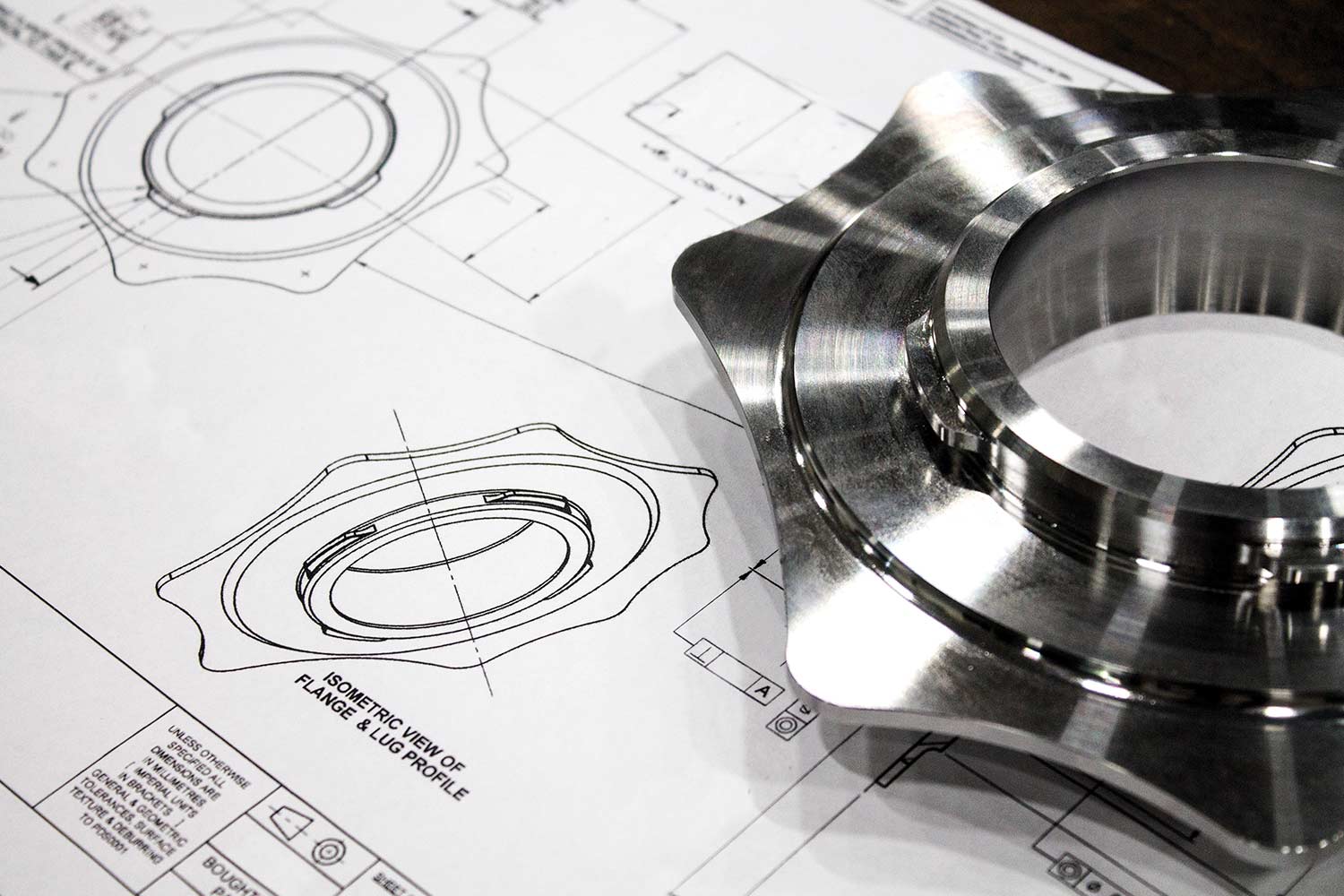

We are looking for an experienced Machinist with a strong understanding and experience of working in a fast-paced machining centre. You must be a self-motivated individual accustomed to accepting responsibility and can be relied upon to use own initiative regarding work scheduling and problem solving. You must be an effective communicator and team member.

Reporting to the team leader, the Machinist will be required to operate CNC Machinery consisting of Fanuc and Mazatrol operating systems. Ensuring that safe working practices are always adhered to, while processing materials ensuring they conform to customers order requirements. You will be responsible for checking all quality and relevant paperwork to ensure that products meet customer requirements.

KNOWLEDGE & EXPERIENCE

Key experience required:

- A recognised apprenticeship or relevant experience.

- Experience and demonstrable skills within CNC Programming, editing, proving new parts off.

- Skills and experience of setting CNC Machine tools to produce high precision components.

- In-depth knowledge of Advanced Manufacturing Techniques.

Ideally, relevant experience and practical experience using the following machinery:

- 2 axis turning, 3 axis milling, 5 axis milling, Cylindrical grinding.

- Multi axis machining centres (Mazak I400)

- Fanuc and Mazatrol Matrix 2 controls.

- Tool room equipment, conventional machine tools etc...

Personal competencies will include:

- A passion for manufacturing, someone who thrives through job satisfaction and getting things done.

- A coherent, logical, and methodical approach to problem solving, drawing on experience and knowledge to overcome problems.

- Comfortable and confident in working on their own initiative, through design development and full production.

- Enjoys working with people with a diverse range of skills, sharing ideas about how to get the required results.

- Pro-active about maintaining and developing their knowledge and skills.

BENEFITS

- 34 days annual holiday, inclusive of bank holidays

- Generous pension scheme

- Life Assurance and Income Protection schemes

- Training and development

About Us

LIBERTY Steel Group, part of the GFG Alliance and a leading GREENSTEEL producer, is a global integrated steel business bringing together assets across the steel supply chain, from production of liquid steel from raw and recycled materials through to high value precision engineered steels. With a total rolling capacity of 20 million tonnes, 200 manufacturing locations globally across 12 countries and employing more than 30,000 people, LIBERTY Steel’s furnaces, mills, services centres and distribution sites across the UK, continental Europe, Australia, the United States and China serve demanding sectors such as construction, energy, aerospace, automotive, and infrastructure. LIBERTY Steel is a leader in sustainable industry with a mission to become Carbon Neutral by 2030 (CN30).

GREENSTEEL

LIBERTY’s GREENSTEEL strategy seeks to transform steel making through increased use of steel recycling in electric arc furnaces (EAF), application of low carbon and renewable energy sources to power industrial processes and use of hydrogen instead of coking coal as a reducing agent for iron ore through Direct Reduce Iron (DRI) plants to remove CO2 emissions from steel making.

Our Purpose and Values

Sustainability

Our STRATEGY is to create an economically viable business model for our industries which is profitable for the long term, allows for socially sustainable development in our local communities and is carbon neutral.

Change

Family

Documents

Alternatively, please sign in with...

Published

Not PublishedClosing

in X days